Core Competency

Manufacturing Site Introduction

The ITW EBA manufacturing site has been based in Taiwan since November 20th, 1969, and our plant has expanded from 4,000 m² to over 12,000 m² in just a few years. The demand for ITW products has continuously increased year by year, and new plants have been built progressively with state-of-the-art facilities to meet customer needs. Here are the five main core competencies of ITW EBA,

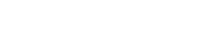

Manufacturing Facilities

Our production consists of assembly, plastic injection, and automated production lines. These production lines use up-to-date technology and devices, allowing our products to remain competitive in the market. One of ITW's philosophies, the "In-lining" strategy, is rooted in our production process to optimize the flow from raw materials to finished goods. This enables our production team to manufacture ITW products efficiently and effectively. ITW Electronics Business Asia provides market-leading equipment in a broad array of electronic assembly applications, along with supporting maintenance, repair, and operations, as well as consumables that serve the electronics, semiconductor, energy storage system, general industrial, and automotive industries.

Global Supply Chain

ITW is a global corporation with seven main business segments: Automotive OEM, Construction Products, Food Equipment, Polymers & Fluid, Specialty Production, Test & Measurement and Electronics, and Welding. Every day, numerous trades and deliveries are completed by ITW, and the overall material demands have a significant impact on raw material suppliers. Our global sourcing team can secure raw materials during global crises or disasters that could potentially disrupt material supply. This ITW resource provides our customers with a stronger and more stable supply chain compared to other companies. Another ITW philosophy, the "MRD" (Market Rate of Demand) inventory strategy, is well-established in ITW EBA to prevent customers from experiencing line-down situations. The inventory will be adjusted according to market demand. ITW EBA is committed to working with suppliers who operate responsibly and with dedication to global environmental sustainability. We strive to foster responsibility across our value chain to ensure that we conduct business to the highest level of integrity and ethical standards.

Quality Assurance

ITW EBA maintains high standards and strict quality control requirements, from incoming materials to outgoing goods, as well as among our engineers and quality management. Our cutting-edge technology is designed to meet the needs of our diverse set of customers operating in highly regulated, demanding environments. Since our company's establishment, we have regularly invested in and upgraded our inspection equipment to improve the user experience of our products. With up-to-date testing equipment and devices, we are able to conduct inspections before, during, and after product manufacturing. Customers can always request inspection reports when purchasing products from ITW EBA. In addition, our quality team can generate test analyses using the inspection equipment that we have invested in. They provide test reports as supporting documents for our customers' applications, which helps to build up their confidence in our products.

ITW ESG & CSR (Corporate Social Responsibility)

ITW’s sustainability strategy is built around four key elements: Our Governance & Ethics, Our People, Our Communities, Our Environment. As part of our vision to be one of the world’s best performing, highest quality and most-respected industrial companies, we will continue to support our communities and our employees to make a difference in the world around us. We focus our efforts on sourcing more environmentally friendly and sustainable materials for our products. Each year, we increase the volume of recycled materials used in our operations where functionality allows. For example:

- Approximately 85 percent of our steel is derived primarily from scrap metal.

- Globally, about 7 percent of our resin consumption is from recycled sources.

- Approximately 16 percent of our addressable solvents and oils are from recycled sources.

For more ITW CSR & Sustainability information, please refer to ITW 2022 Sustainability Report link below,

R&D Capability

With over 50 years of experience in switches, fasteners, connectors, and IC packaging, our R&D team is capable of providing customers with critical solutions. Solving customer pain points is ITW's profession, and we offer customized services to meet all kinds of customer requirements. Our R&D team follows global trends in automation and innovation is at our core. With strong brand positions, technical expertise, and in-depth market knowledge, we provide value-added test and measuring solutions, supported by strong service and aftermarket capabilities. Our production line features many high-tech automated machines and robotic arms to enhance productivity and reduce labor and operating costs. In order to offer customers cost-effective and competitive products, our R&D team cooperates with customers in every stage of development and provides professional solutions.